About Us

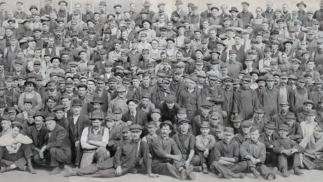

For more than 150 years, A. O. Smith has delivered innovative solutions to millions of consumers, business owners, property managers and professionals worldwide.

As a global leader, A. O. Smith prides itself on applying innovative technology and energy-efficient solutions to water technology products marketed worldwide. The company focuses heavily on new product development, global expansion, strategic acquisitions and partnerships to achieve this goal.

The company was founded in 1874 in Milwaukee, Wisconsin, where it is still headquartered today. A. O. Smith employs more than 12,700 individuals at operations in the United States, Canada, Mexico, China, India, the United Kingdom and the Netherlands. We also have sales and distribution in more than 60 countries around the world.

Global Operations

A. O. Smith Corporation World Headquarters

11270 West Park Place,

Suite 170

Milwaukee, WI 53224

Global Locations

North America

Appleton, Wisconsin - residential, commercial water treatment systems for North America, Europe and South America; water treatment system sales and distribution for local region

Ashland City, Tennessee - residential gas and electric water heaters for North America; headquarters for the North America Water Heating (NAWH) business unit

Austin, Texas - sales and marketing of water treatment products for North America

Charlotte, North Carolina - pump tanks and pressure tanks for North America

Ciudad Juárez, Chihuahua, Mexico - residential gas and electric water heaters and heat pump water heaters for North America

Cookeville, Tennessee - water heater components

El Paso, Texas – distribution center for residential gas and electric water heaters and heat pump water heaters for North America

Fergus, Ontario, Canada - distribution center for residential and commercial water heaters; headquarters for the NAWH Canadian business

Florence, Kentucky - porcelain enamel coatings and specialty glass

Franklin, Tennessee - water heater components

Groveport, Ohio - water treatment products for North America

Haltom City, Texas - water treatment system assembly and logistics for North America

Johnson City, Tennessee - residential and light commercial gas and electric water heaters for North America

Knoxville, Tennessee - steel cut sheets for residential and commercial water heaters

Las Vegas, Nevada – light assembly and distribution for local region

Lebanon, Tennessee - residential and commercial boilers, commercial water heaters and storage tanks for North America; Product Development Center for North America

McBee, South Carolina - commercial gas and electric water heaters and copper tube boilers for North America

Milwaukee, Wisconsin – global corporate headquarters and Corporate Technology Center

Montréal, Québec, Canada - commercial and residential electric, gas and oil-fired water heaters for Canada

Nashville, Tennessee – business and technology solutions, corporate financial department and global manufacturing operations

Ontario, California – assembly and shipment of water treatment equipment for North America

Phillipsburg, Kansas - synthetic zeolites designed for water treatment, air filtration, odor removal and other unique applications for North America and Europe

Pottstown, Pennsylvania – assembly and shipment of water treatment systems for North America

Rancho Cucamonga, California – distribution center for commercial and residential electric heat pumps for North America

Stratford, Ontario, Canada - pump tanks and pressure tanks for North America

Tucson, Arizona - water treatment system sales and distribution for Southwest U.S.

West Palm Beach, Florida - water treatment system sales and distribution for Southeast U.S. and South America

Europe & Middle East

Banbury, United Kingdom - boilers, water heaters, heat pumps, solar thermal and associated ancillary equipment for the United Kingdom and Ireland

Bourges, France - sales and service of commercial and residential gas and electric water heaters, storage and indirect tanks, heat pumps, solar thermal and associated ancillary equipment for France

Dubai, United Arab Emirates - wholesale and retail water heater and water purifier sales for Africa and the Middle East

Lyon, France – water treatment systems sales for southern Europe

Veldhoven, the Netherlands - commercial and residential gas and electric water heaters, solar water heaters and heat pumps, boilers, storage and indirect tanks for Europe and the Middle East

Asia & Pacific

Bengaluru, India - residential electric water heaters for India

Colombo, Sri Lanka – residential water treatment sales and distribution for Sri Lanka

Dhaka, Bangladesh – residential water treatment sales and distribution for Bangladesh

Ho Chi Minh City, Vietnam - residential water treatment sales and distribution for Vietnam

Hong Kong, SAR - Asian export business, Hong Kong business, strategic planning, business development and management services in Asia

Mumbai, India - research and development; residential water treatment sales and distribution for India

Nanjing, China - China corporate headquarters, Corporate Technology Center, reverse osmosis water purification and filtration products, residential and commercial gas and electric water heaters, and kitchen appliances for China